Case Study: Successful Implementation of Compressor Systems in Romanian Industries

Introduction to Compressor Systems in Romania

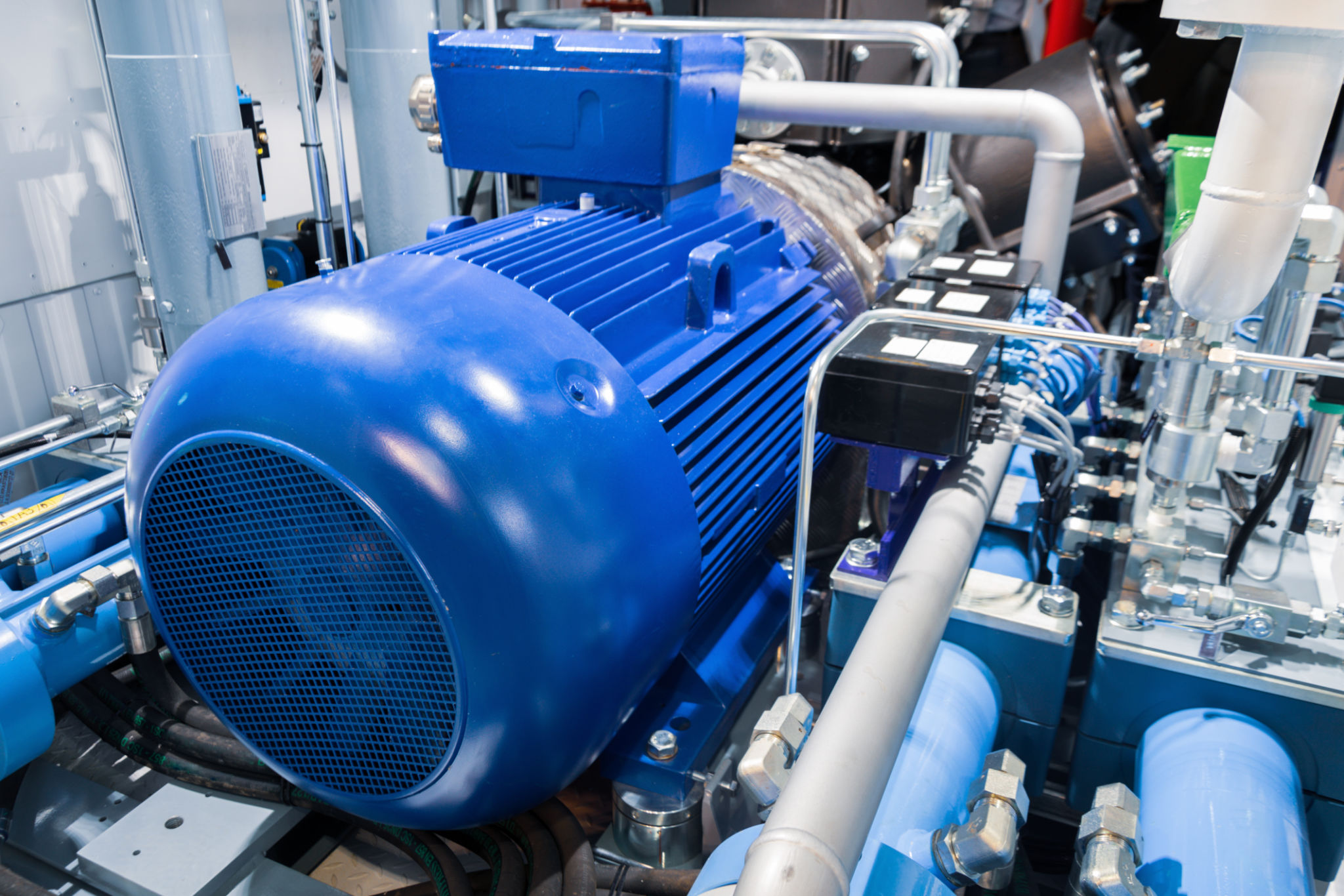

The industrial landscape of Romania has seen significant advancements over the past few years, particularly with the implementation of modern compressor systems. These systems play a crucial role in enhancing operational efficiency in various sectors, including manufacturing, energy, and construction. By improving air quality and reducing energy consumption, compressor systems have become indispensable in Romanian industries.

In this case study, we explore how different industries in Romania have successfully integrated compressor systems into their operations. We will examine the benefits realized, challenges faced, and the strategic steps taken to ensure a smooth implementation process.

Benefits of Compressor Systems

Enhanced Efficiency

One of the primary advantages of compressor systems is their ability to significantly enhance operational efficiency. By optimizing air pressure and delivering consistent performance, these systems reduce downtime and maintenance costs. Romanian companies have reported up to a 30% increase in productivity after integrating advanced compressor technologies.

Energy Savings

Energy efficiency is another crucial benefit that Romanian industries have experienced. Compressor systems are designed to minimize energy waste, leading to substantial cost savings. In fact, businesses across Romania have observed a reduction in energy consumption by approximately 20%, thanks to the implementation of state-of-the-art compressors.

Key Industries Benefiting from Compressor Systems

Manufacturing Industry

The manufacturing sector in Romania has been one of the biggest beneficiaries of compressor technology. These systems are used extensively in processes such as assembly line operations, machinery maintenance, and quality control. By ensuring a stable and efficient supply of compressed air, manufacturers can maintain high production standards while reducing operational costs.

Construction Sector

In the construction industry, compressor systems are vital for powering tools and machinery. Companies have found that reliable compressor systems enhance the performance of pneumatic tools, leading to faster project completion times and improved safety standards on-site.

Challenges and Solutions in Implementation

Addressing Technical Complexities

Despite their benefits, integrating compressor systems comes with its own set of challenges. Romanian industries have had to address technical complexities related to installation and maintenance. To overcome these hurdles, companies have invested in training programs for their staff and partnered with experienced vendors who offer comprehensive support services.

Cost Management

The initial cost of acquiring high-quality compressor systems can be significant. However, Romanian businesses have managed these expenses by opting for leasing options or financing plans that distribute costs over time. This approach allows them to reap the immediate benefits of advanced compressor technology without straining their budgets.

Conclusion

The successful implementation of compressor systems has had a transformative impact on Romanian industries. By boosting efficiency, reducing energy consumption, and supporting key industries like manufacturing and construction, these systems have become integral to industrial operations. While challenges exist, strategic planning and investment in technology and training have enabled Romanian businesses to fully harness the potential of modern compressor systems.

As industries continue to innovate and seek sustainable solutions, the role of compressor systems will only grow. This case study highlights not only the current successes but also the promising future for Romanian industries leveraging this essential technology.