Common Misconceptions About Compressed Air Systems: What You Really Need to Know

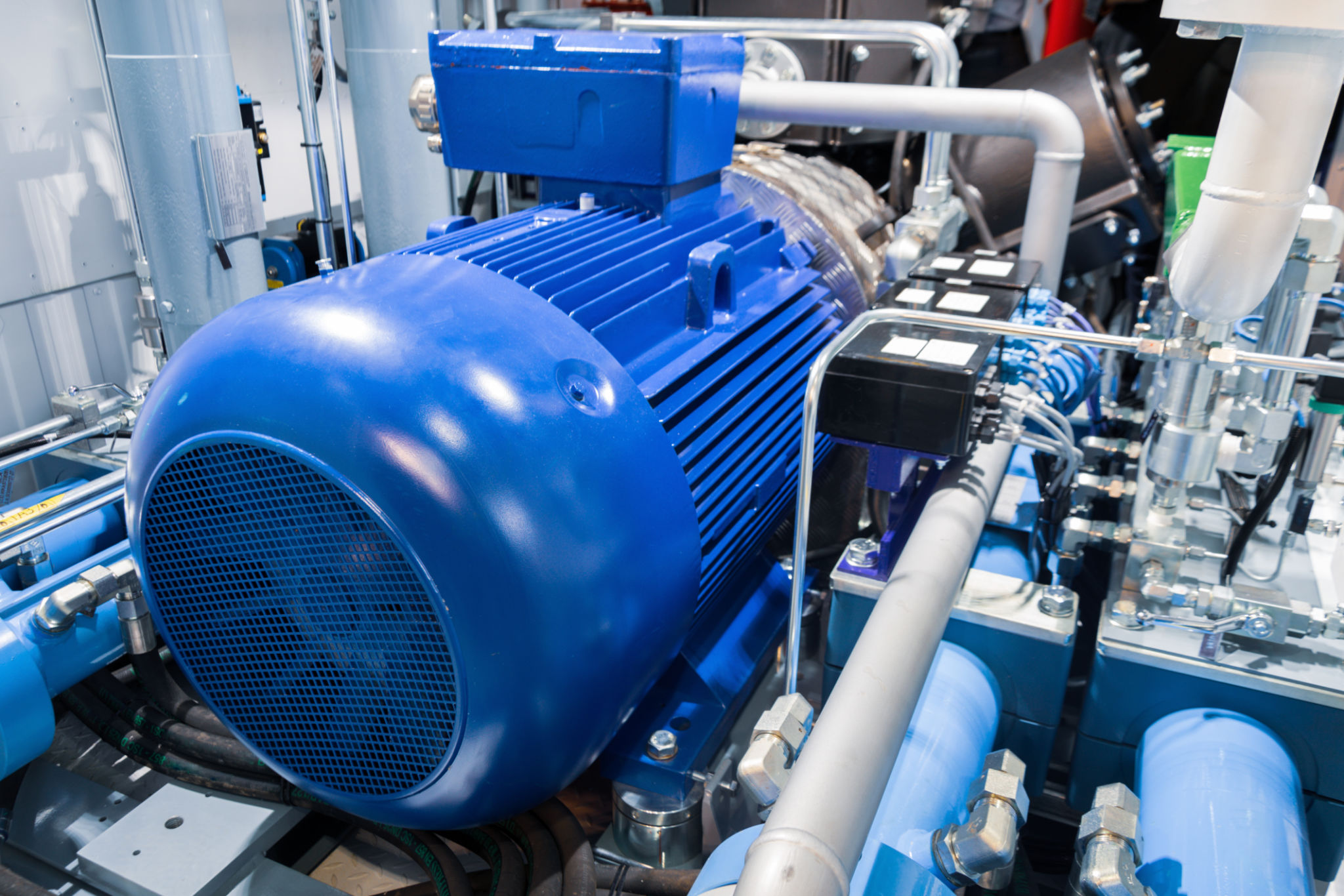

The Reality of Compressed Air Systems

Compressed air systems are often considered a straightforward aspect of industrial operations. However, several misconceptions persist, leading to inefficiencies and potential operational issues. Understanding these myths is crucial for optimizing performance and reducing costs.

Misconception 1: Compressed Air is Free

One of the most common misconceptions is that compressed air is a free resource. While the air itself costs nothing, the process of compressing it is energy-intensive. Approximately 70% of the total cost of a compressed air system over its lifetime is energy-related. Therefore, investing in efficient systems and regular maintenance can lead to significant savings.

Misconception 2: Bigger is Always Better

Many believe that installing a larger compressor than necessary will ensure better performance. However, oversized compressors can lead to increased energy consumption and more frequent maintenance issues. It's essential to match the compressor size to the actual demand to ensure efficiency and longevity.

Misconception 3: Low Pressure Equals Low Efficiency

There's a general belief that lower pressure settings result in reduced efficiency. In reality, operating at a pressure higher than needed can waste energy. Systems should be evaluated regularly to determine the optimal pressure setting for the specific applications they support.

Misconception 4: Maintenance is a Low Priority

Some operators assume that compressed air systems require minimal maintenance, but this couldn't be further from the truth. Regular maintenance is vital to prevent leaks, which can account for up to 30% of air loss in a system. Routine checks and timely repairs can not only prevent leaks but also enhance overall system performance.

Additional Considerations for Optimal Performance

Beyond debunking these myths, there are additional steps you can take to ensure your compressed air system operates efficiently:

- Invest in quality components: Using high-quality hoses, fittings, and filters can reduce the risk of leaks and prolong system life.

- Regularly train personnel: Ensure that all operators are well-trained in the proper use and maintenance of compressed air systems.

- Conduct energy audits: Periodic energy audits can help identify inefficiencies and areas for improvement.

The Importance of Proper Installation

Proper installation is often overlooked but plays a critical role in system efficiency. Incorrect installation can lead to pressure drops, leaks, and increased energy consumption. Engaging experienced professionals for installation and commissioning ensures that the system is set up according to best practices.

Conclusion: Knowledge is Power

Understanding the realities of compressed air systems can significantly impact your operations. By dispelling common myths and focusing on efficiency, maintenance, and proper installation, you can achieve substantial cost savings and improve system reliability. Remember, knowledge and proactive management are key to maximizing the benefits of compressed air systems in your operations.