Common Misconceptions About Industrial Compressors: What You Need to Know

Understanding the Role of Industrial Compressors

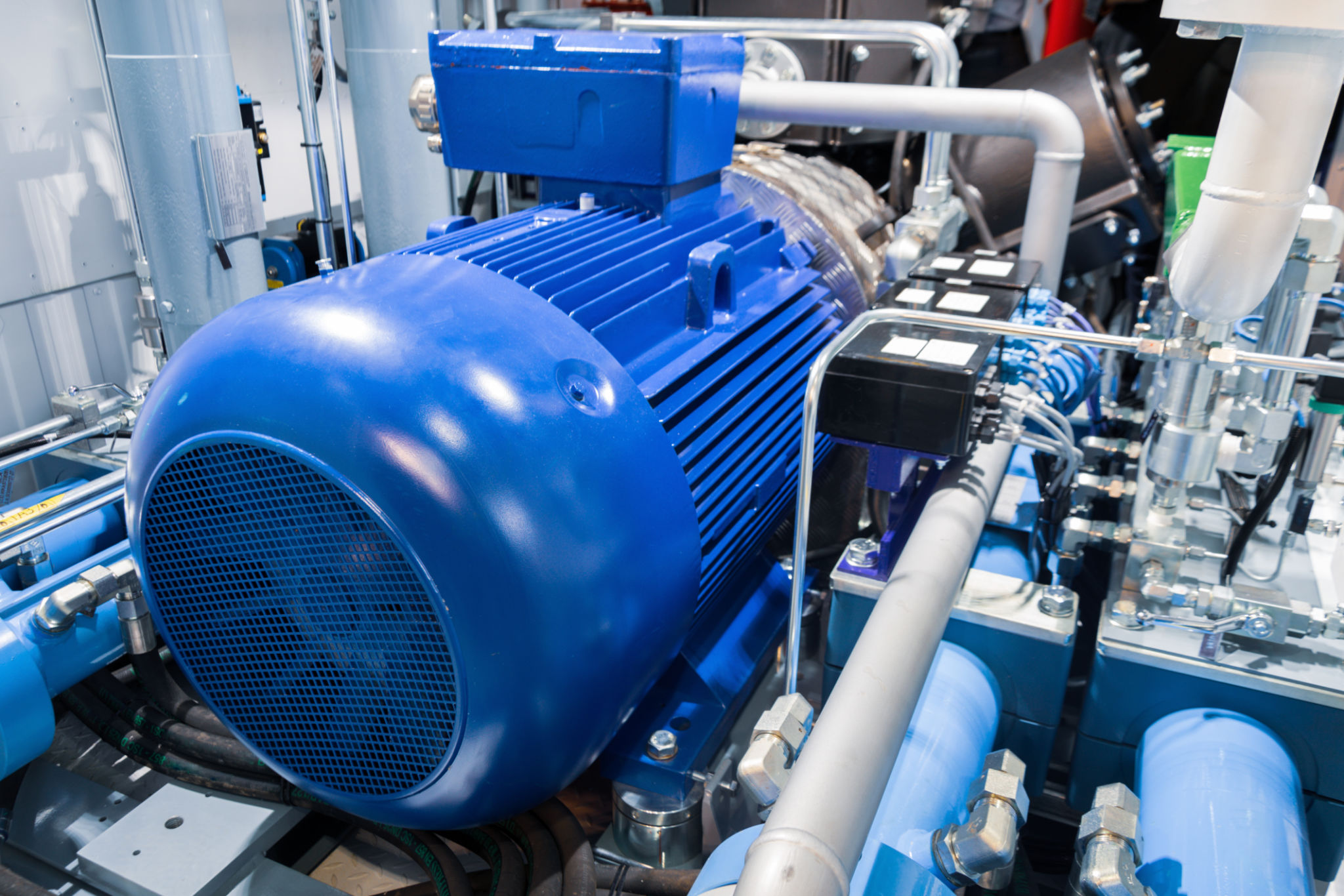

Industrial compressors play a critical role in many manufacturing and processing operations. Despite their importance, several misconceptions about these machines persist. Understanding the truth behind these misconceptions can help businesses make informed decisions when selecting and maintaining compressors.

Misconception 1: All Compressors Are the Same

One common misconception is that all industrial compressors are the same, and any model will suffice for any application. In reality, compressors come in a variety of types, including reciprocating, rotary screw, and centrifugal compressors, each designed for specific tasks. Choosing the right type depends on the intended application, pressure requirements, and operational environment.

Misconception 2: Compressors Do Not Require Regular Maintenance

Another widespread belief is that industrial compressors are maintenance-free. This is far from the truth. Regular maintenance is crucial to ensure their longevity and efficiency. Neglecting routine checks can lead to decreased performance, higher energy consumption, and costly repairs. Implementing a proactive maintenance schedule can prevent these issues.

Misconception 3: Size Equals Power

A significant misconception is that the larger the compressor, the more powerful it is. While size can indicate capacity, it does not necessarily correlate with power or efficiency. Factors such as design, technology, and application suitability play a more critical role in determining a compressor's effectiveness. It's essential to evaluate these aspects rather than rely solely on size.

The Importance of Energy Efficiency

Energy efficiency is often overlooked when selecting an industrial compressor. Many assume that all compressors use similar amounts of energy. However, choosing an energy-efficient model can lead to substantial savings in operational costs and a smaller carbon footprint. Opting for models with variable speed drives (VSDs) can further enhance efficiency by adjusting the compressor's output to match demand.

Misconception 4: Compressors Are Too Noisy

Noise is another area where misconceptions abound. While it's true that some older compressor models are noisy, modern designs have significantly reduced noise levels. Innovations in soundproofing and vibration reduction make many contemporary compressors suitable for environments where noise levels must be minimized.

Misconception 5: Compressors Are a One-Time Investment

Lastly, some believe that purchasing an industrial compressor is a one-time investment. However, the total cost of ownership includes not just the initial purchase price but also installation, maintenance, energy consumption, and potential downtimes. Evaluating these factors helps in understanding the long-term costs associated with compressors.

In conclusion, dispelling these misconceptions about industrial compressors is essential for making informed decisions in any industrial setting. By understanding the different types of compressors, the importance of maintenance, and factors influencing efficiency and cost, businesses can optimize their operations and enhance productivity.