Debunking Myths: Common Misconceptions About Industrial Compressors

Understanding Industrial Compressors

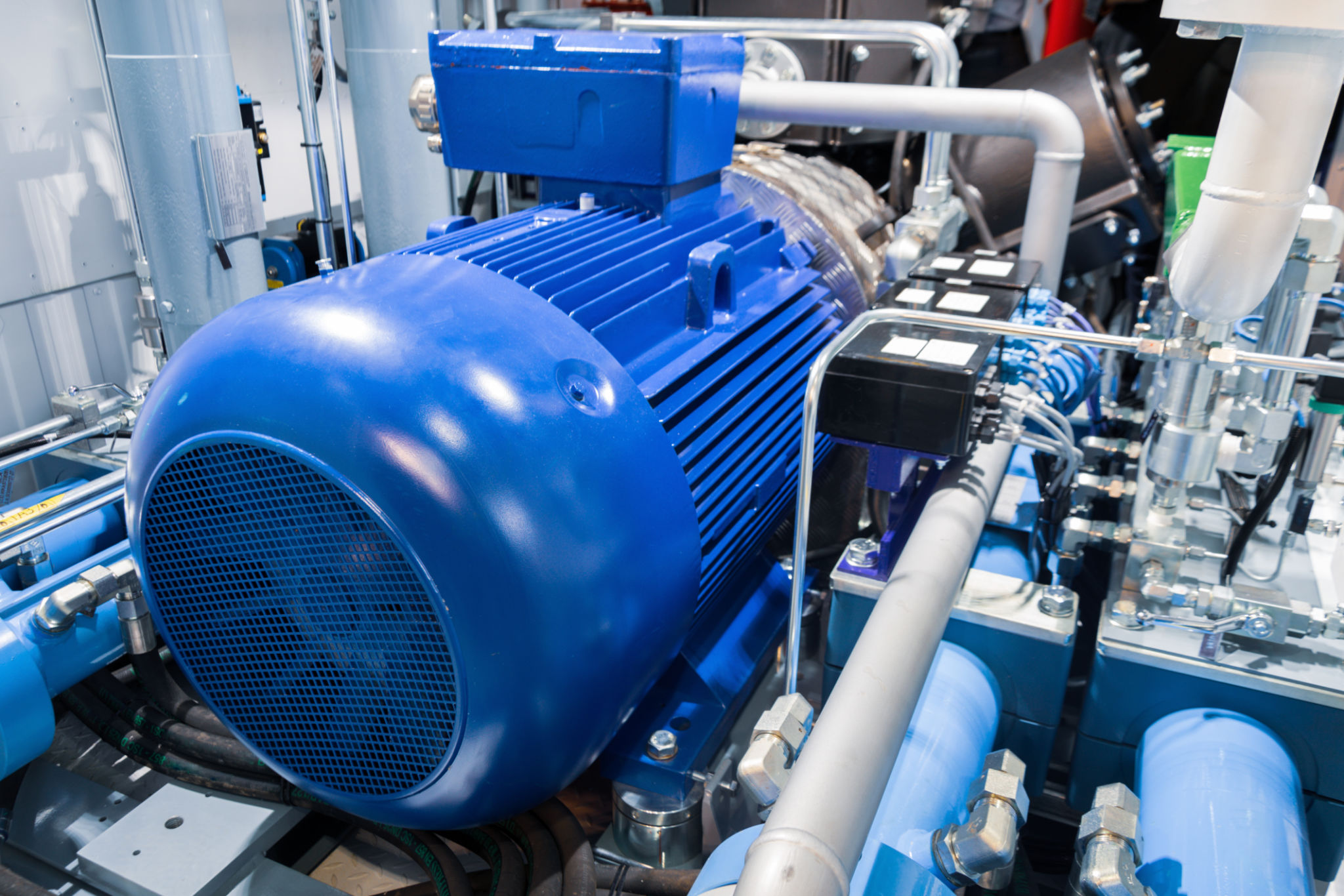

Industrial compressors are integral to many industries, yet they are often misunderstood. These devices, used to increase the pressure of gases, play a crucial role in various applications. By debunking common myths surrounding them, we can better appreciate their functionality and importance.

Myth 1: Compressors Only Serve One Purpose

A prevalent myth is that industrial compressors serve a singular purpose. In reality, their applications are vast and diverse. They are used in industries ranging from manufacturing and energy to healthcare and food processing. Compressors are essential for tasks such as powering pneumatic tools, cooling and refrigeration, and even facilitating chemical processes.

The misconception likely arises from a lack of awareness about the different types of compressors and their specific uses. Whether it's a rotary screw, reciprocating, or centrifugal compressor, each type is designed to meet the demands of specific applications.

Myth 2: All Compressors Are the Same

Another common misconception is that all compressors operate in the same way. This couldn't be further from the truth. There are several types of compressors, each with unique mechanisms and uses:

- Reciprocating Compressors: These use pistons driven by a crankshaft to deliver gases at high pressure.

- Rotary Screw Compressors: Known for their efficiency and continuous operation capabilities.

- Centrifugal Compressors: Ideal for large-scale operations due to their high flow rate capacity.

The choice of compressor depends on factors such as the desired pressure level, application type, and operational efficiency.

Myth 3: Compressors Don't Require Regular Maintenance

Some believe that once installed, compressors require little to no maintenance. However, like any other machinery, regular upkeep is critical to ensure optimal performance and longevity. Routine maintenance includes checking for leaks, replacing filters, and monitoring oil levels.

Neglecting maintenance can lead to costly repairs and downtime. Implementing a proactive maintenance schedule can help identify potential issues before they escalate.

Myth 4: Energy Consumption Is Insignificant

A significant myth is that compressors don't consume much energy. In fact, they can be substantial contributors to an industrial facility's energy usage. However, modern compressors are designed with energy efficiency in mind. Using variable speed drives and implementing energy management systems can significantly reduce energy consumption.

By understanding these myths and the realities behind them, industries can make informed decisions about their compressor needs and maintenance practices. As technology advances, staying updated with the latest developments in compressor technology is essential for maximizing efficiency and minimizing costs.

Conclusion

Industrial compressors are complex machines with diverse applications across numerous industries. By dispelling these common misconceptions, businesses can better capitalize on the benefits these powerful tools offer. Emphasizing proper selection, maintenance, and energy efficiency can lead to improved productivity and cost savings in the long run.