DIY Air Compressor Troubleshooting: Solving Common Issues

Understanding the Basics of Air Compressors

Air compressors are essential tools in many DIY projects, providing the power needed for various pneumatic tools. However, like any machinery, they can encounter issues. Understanding the basics of how air compressors operate can help in diagnosing and fixing common problems efficiently.

Generally, air compressors work by converting power into potential energy stored in pressurized air. This process involves several components, including the motor, compressor pump, and storage tank. Knowing these parts and their functions can make troubleshooting much easier.

Common Air Compressor Issues

Compressor Not Starting

If your air compressor doesn't start, the problem could be as simple as a power supply issue. Ensure the compressor is plugged in properly and that the outlet is working. Additionally, check the fuse or circuit breaker to make sure they haven't tripped.

Low Pressure Output

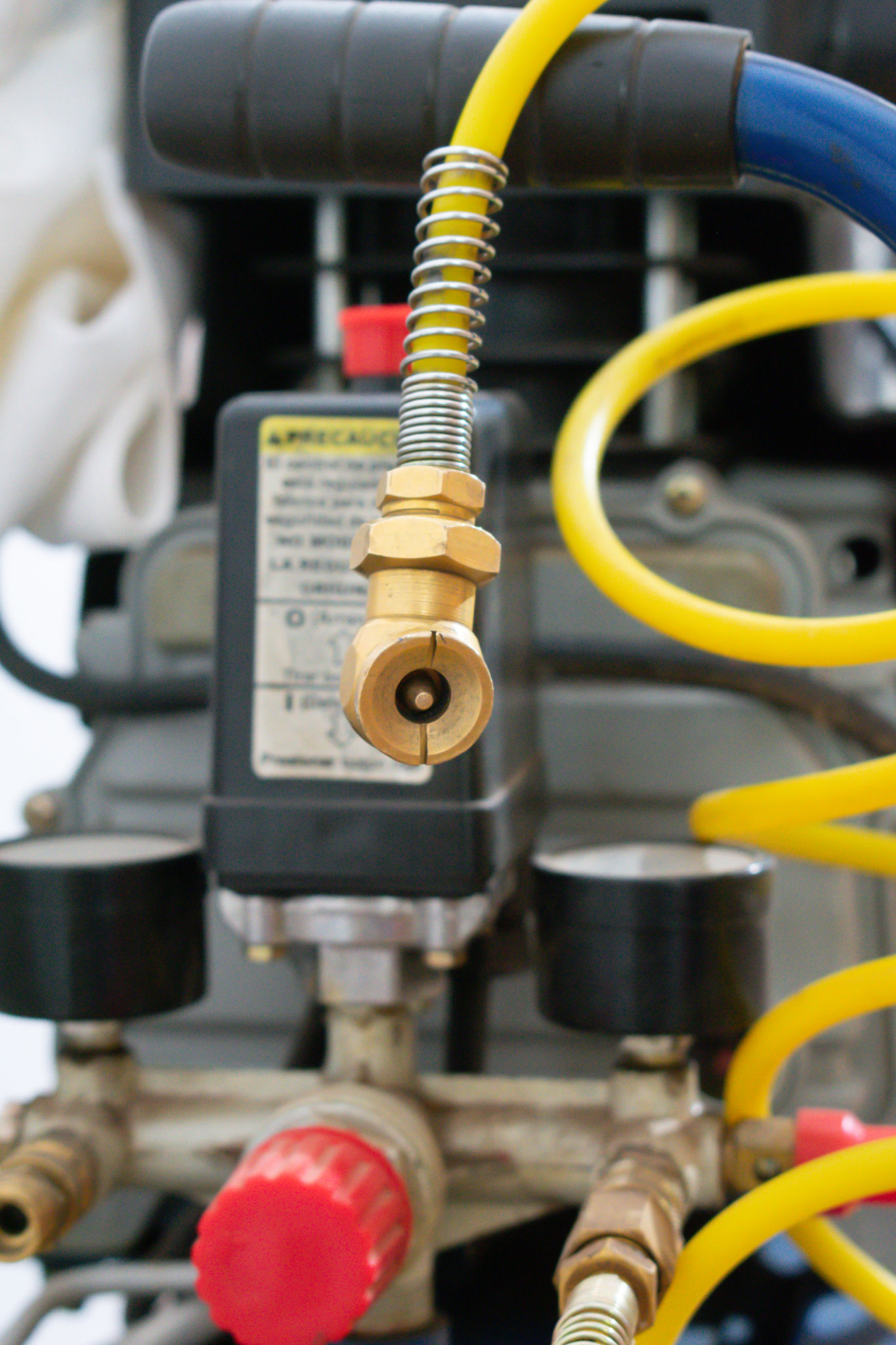

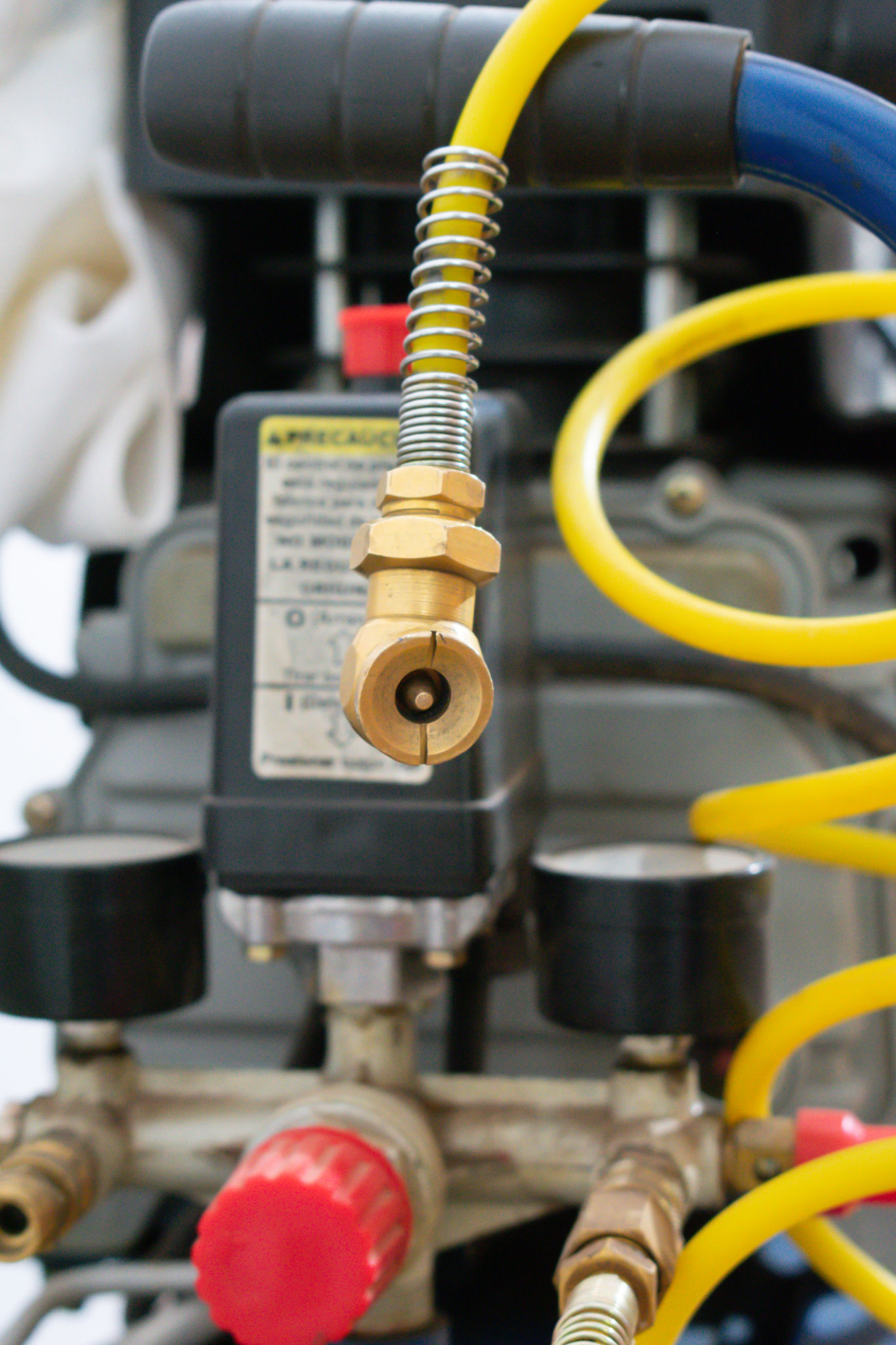

Low pressure output is another frequent issue. This could be due to a leak in the system, so inspect hoses and connections for any signs of wear or damage. Check the seals and replace them if necessary to ensure a tight fit.

Troubleshooting Noisy Operation

A noisy air compressor can be a nuisance and may indicate underlying problems. The noise might come from loose parts or components that need lubrication. Tighten any loose screws and apply oil to moving parts to reduce friction.

If the noise persists, it could be due to worn-out bearings or damage in the motor. In such cases, consult the manufacturer's manual or consider professional repair services.

Handling Overheating Issues

Overheating is a common problem, especially in older models or when used extensively. Ensure that the compressor has adequate ventilation and is not in a confined space. Regularly clean the air filter to prevent clogs that could cause overheating.

Checking for Oil Levels

Some air compressors require oil for lubrication. Low oil levels can lead to increased friction and overheating. Regularly check and refill the oil to maintain optimal performance and prevent damage to the internal components.

Conclusion: Regular Maintenance is Key

Consistent maintenance can prevent many common air compressor issues from arising. By performing regular checks on electrical connections, seals, and oil levels, you can extend the lifespan of your equipment. Never hesitate to consult your compressor's manual for specific guidance or reach out to professionals when needed.

By understanding these common issues and their solutions, you can ensure that your air compressor remains a reliable tool in your DIY arsenal. With proper care, you can avoid costly repairs and keep your projects running smoothly.