How to Maintain Your Industrial Air Compressor for Optimal Performance

Understanding the Importance of Regular Maintenance

Maintaining your industrial air compressor is essential for ensuring its optimal performance and longevity. Regular maintenance not only helps in preventing unexpected breakdowns but also enhances efficiency, saving both time and money in the long run. Industrial air compressors play a critical role in various operations, and any downtime can have significant impacts on productivity.

Developing a Maintenance Schedule

To keep your air compressor running smoothly, establish a regular maintenance schedule. This schedule should include daily, weekly, monthly, and annual checks to cover all aspects of the compressor's operation. Make sure to follow the manufacturer's recommendations for maintenance intervals and procedures to ensure that all necessary tasks are completed on time.

Daily and Weekly Maintenance Tasks

Daily checks are crucial for catching potential issues early. Each day, inspect the compressor for any unusual noises or vibrations. Ensure that the oil levels are adequate and that there are no visible leaks. Additionally, make sure to drain moisture from the air receiver tank to prevent water buildup, which can lead to corrosion.

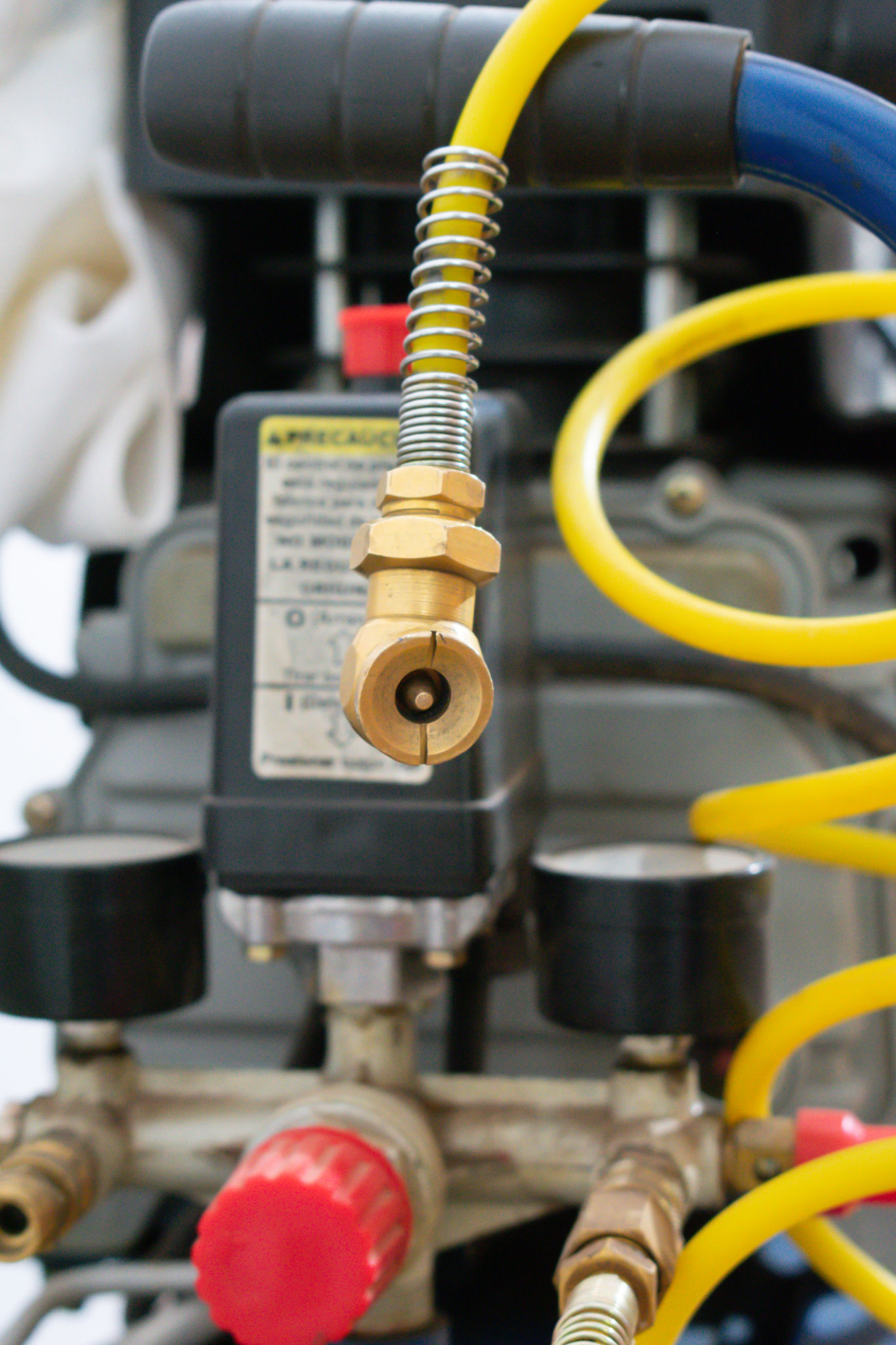

Weekly maintenance should include checking the condition of air filters. Dirty or clogged filters can reduce efficiency and increase energy consumption. Replace them if necessary to ensure proper airflow. Also, inspect hoses and connections for wear or damage and ensure that safety mechanisms are functioning correctly.

Monthly and Annual Maintenance Checks

Monthly inspections involve more in-depth checks, such as examining belts for tension and wear. A loose or worn belt can lead to inadequate performance or even damage to the compressor. Make sure to tighten or replace belts as necessary. Additionally, check the oil cooler for any debris or obstructions that might impede airflow.

Annual maintenance is a comprehensive checkup that often requires professional assistance. During this inspection, ensure that all components are thoroughly cleaned and lubricated. It's also essential to test the compressor's electrical systems and controls to confirm they are functioning correctly. Proactive care during these annual checks can prevent costly repairs down the line.

The Role of Professional Servicing

While regular maintenance can be performed by in-house personnel, periodic professional servicing is crucial for identifying issues that might not be apparent during routine checks. Professional technicians have the expertise and tools required to conduct in-depth inspections and repairs, ensuring your compressor remains in top condition.

Benefits of Keeping Maintenance Logs

Maintaining detailed logs of all maintenance activities is beneficial for tracking the performance of your air compressor over time. These records can help identify patterns or recurring issues, allowing you to address them proactively. Logs also serve as valuable documentation for any warranty claims or when selling or upgrading equipment.

Conclusion

By adhering to a structured maintenance routine and incorporating professional inspections, you can significantly enhance the performance and lifespan of your industrial air compressor. Consistent care not only minimizes downtime but also ensures that your operations run smoothly, ultimately contributing to cost savings and increased productivity.