Seasonal Maintenance Tips for Industrial Air Compressors in Romania

Understanding the Importance of Seasonal Maintenance

Ensuring the proper functioning of industrial air compressors is crucial for maintaining optimal productivity and efficiency in any manufacturing facility. In Romania, where seasonal changes can be quite pronounced, it is essential to adapt your maintenance practices accordingly. By understanding the specific needs and challenges each season presents, businesses can prevent costly downtime and extend the lifespan of their equipment.

Preparing for the Winter Months

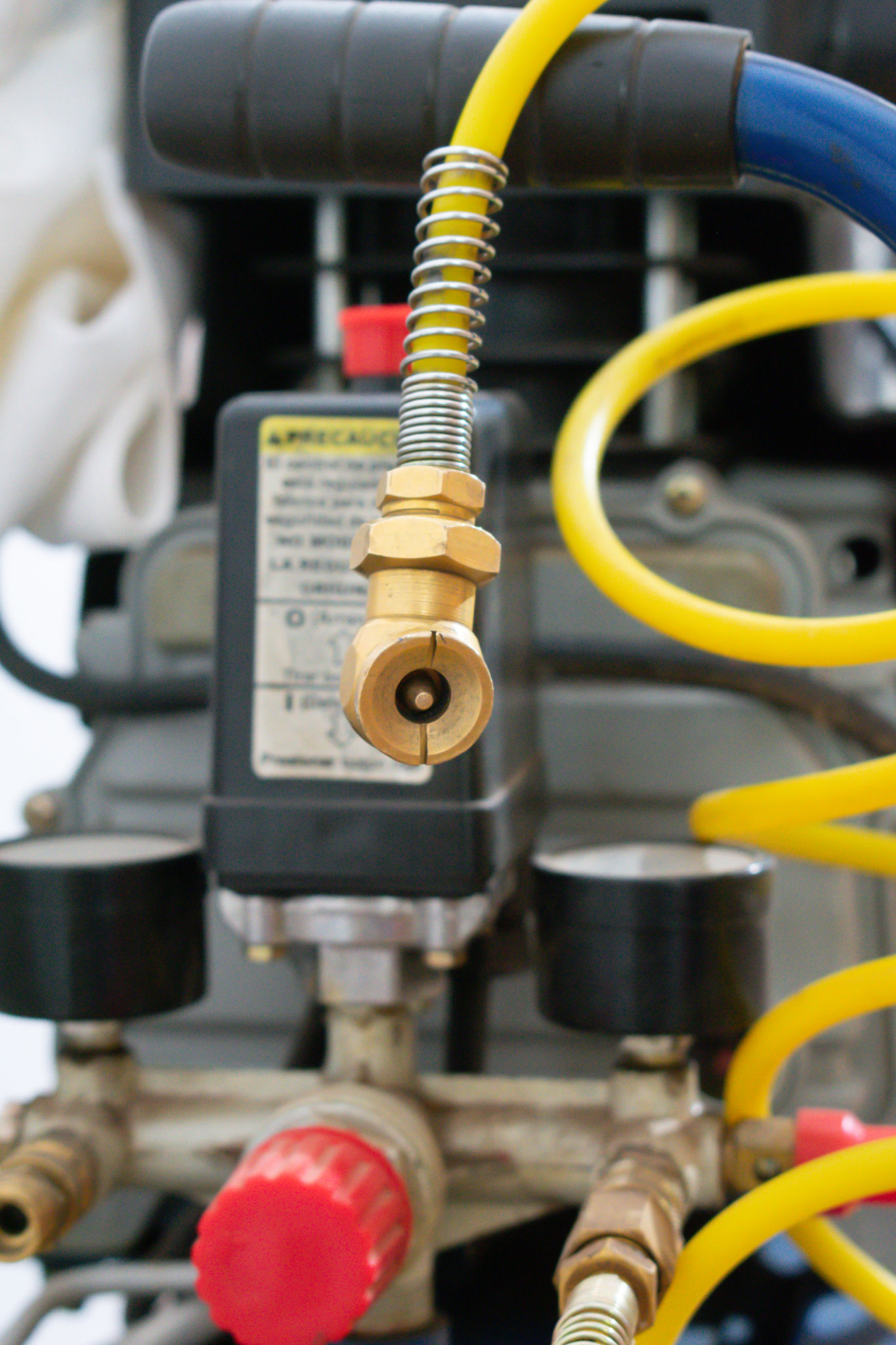

Winter in Romania can bring cold temperatures that impact the performance of air compressors. It's vital to inspect your system for any signs of wear and tear before the cold sets in. One critical step is to check for moisture buildup, as freezing temperatures can cause moisture to solidify, leading to blockages and increased wear.

To avoid such issues, ensure that your air compressor's dryer is functioning correctly and the condensate drains are clear. Additionally, consider using synthetic oil, which performs better in colder temperatures, ensuring smoother operation and reduced friction.

Spring Cleaning and Inspection

As temperatures begin to rise, spring is an excellent time to conduct a thorough inspection and cleaning of your air compressor system. Start by replacing any filters that have accumulated dust and debris over the winter months. Clean or replace air intake filters to maintain efficient airflow and reduce strain on the compressor.

Inspect all belts and hoses for signs of cracking or wear. Spring is also the perfect time to recalibrate your equipment, ensuring that all settings are optimized for the upcoming warmer months. Regular inspections can prevent minor issues from escalating into major, costly repairs.

Summer Cooling Strategies

The summer heat in Romania can push air compressors to their limits. High temperatures can lead to overheating, so it's crucial to focus on keeping your equipment cool. Ensure that your compressor's cooling systems, such as fans and ventilation, are clean and operational.

Consider installing additional cooling fans or even relocating your compressor to a cooler area if possible. Monitor oil levels regularly, as higher temperatures can lead to faster evaporation and reduced lubrication efficiency.

Preparing for Autumn Challenges

Autumn is a transitional period that offers an opportunity to address any summer-induced wear. As leaves fall, ensure that outdoor air compressors are protected from debris that could clog air intakes or vents. Conduct a comprehensive check of all electrical connections, as fluctuating temperatures can affect conductivity.

Additionally, review your maintenance logs to identify any recurring issues that might need attention before winter arrives. Implementing preventive measures during autumn can save time and resources during the busier winter months.

Conclusion: The Value of a Proactive Approach

By adopting a proactive approach to seasonal maintenance, businesses in Romania can ensure their industrial air compressors operate efficiently year-round. Regular inspections, timely adjustments, and adherence to best practices tailored to each season will not only enhance performance but also extend the life of your equipment.

Investing time in seasonal maintenance ultimately leads to increased reliability, reduced operational costs, and a smoother production process. Stay ahead of potential issues by adhering to these seasonal maintenance tips, and enjoy uninterrupted productivity throughout the year.