Summer Maintenance for Air Compressors: Essential Tips for Maximum Efficiency

Understanding the Importance of Summer Maintenance

As temperatures rise during the summer months, air compressors can face increased stress and potential performance issues. Ensuring they are well-maintained during this time is crucial for maintaining maximum efficiency and longevity. A proactive approach to maintenance can prevent unexpected breakdowns and costly repairs.

The heat of summer can cause air compressors to overheat, leading to decreased efficiency and potential damage. Regular maintenance checks help in identifying and addressing issues before they escalate. This not only improves performance but also extends the lifespan of the equipment.

Regular Inspection and Cleaning

Check Filters and Replace if Necessary

During summer, the demand on air compressors often increases, making it essential to inspect and clean filters regularly. Dirty or clogged filters can restrict airflow, causing the compressor to work harder than necessary. Ensure that filters are checked at least once a month and replaced as needed to maintain optimal performance.

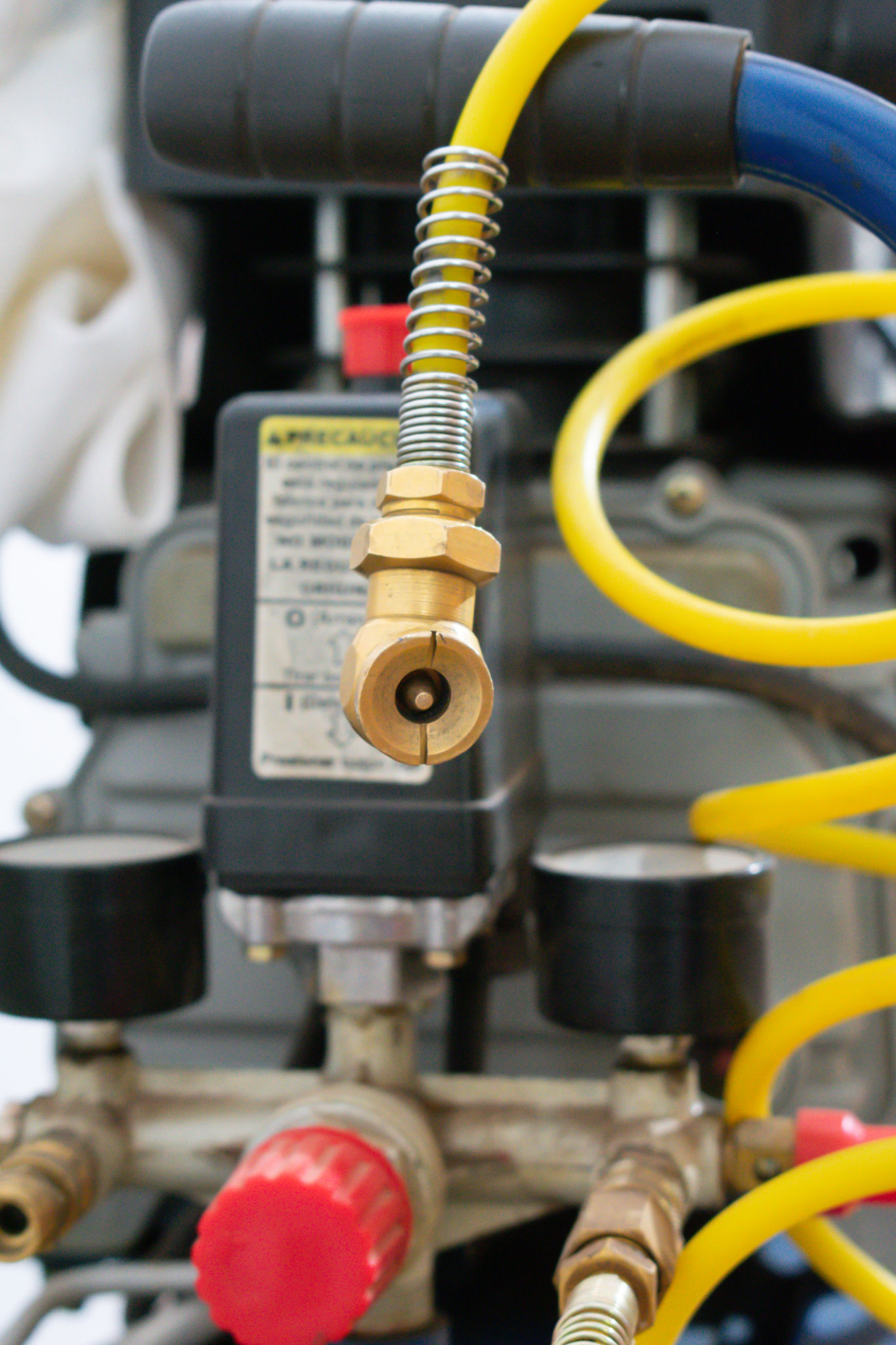

Inspect Belts and Connections

Belts and connections are vital components that require regular inspection during summer maintenance. Check for any signs of wear, cracks, or looseness. Tighten any loose connections and replace worn-out belts promptly. Properly maintained belts ensure efficient operation and prevent unnecessary strain on the compressor motor.

Lubrication and Cooling Systems

Keep It Lubricated

Lubrication is essential for preventing friction between moving parts in an air compressor. During the summer, it's important to check oil levels frequently and top up or replace the oil as necessary. Using the correct type of oil recommended by the manufacturer ensures smooth operation and reduces wear and tear.

Monitor Cooling Systems

Air compressors generate a lot of heat, especially when operating in high temperatures. Ensure that cooling systems such as fans and heat exchangers are functioning correctly. Clean any dust or debris that may have accumulated on cooling fins to improve heat dissipation.

Addressing Moisture Issues

Increased humidity during summer can lead to moisture accumulation in air compressors, which can cause corrosion and damage internal components. Consider using moisture separators or dryers to remove excess water from compressed air. Regularly drain any accumulated moisture from tanks to prevent rust and other related issues.

Check Pressure Settings

Pressure settings can drift over time due to temperature changes or mechanical adjustments. Verify that the pressure settings are within the recommended range for your specific compressor model. Adjust as necessary to ensure efficient operation without overloading the system.

Conclusion: Stay Proactive with Maintenance

Summer maintenance for air compressors is an essential task that should not be overlooked. By following these tips, you can ensure your equipment runs smoothly, efficiently, and reliably throughout the hot months. Regular inspections, timely replacements, and proper lubrication are key to preventing costly downtime and extending the life of your air compressor.

Being proactive with maintenance not only optimizes performance but also provides peace of mind knowing that your equipment is ready to handle the demands of summer operations.