Summer Maintenance Tips for Air Compressors: Ensure Peak Performance

Understanding the Importance of Air Compressor Maintenance

Summer brings with it increased demands on machinery, including air compressors. As temperatures rise, so does the risk of overheating and wear. Ensuring your air compressor is in peak condition is essential for maintaining efficiency and prolonging its lifespan. Regular maintenance not only prevents unexpected breakdowns but also enhances performance, saving you time and resources in the long run.

Check and Replace Filters

One of the simplest yet most effective maintenance tasks is checking and replacing filters. Filters are crucial for keeping unwanted particles out of the compressor, preventing damage and inefficiency. During summer, with higher dust levels and humidity, filters can clog more quickly. Inspect them regularly and replace as necessary to maintain optimal airflow and performance.

Monitor and Maintain Optimal Oil Levels

Oil plays a vital role in the smooth operation of air compressors by lubricating moving parts and reducing friction. During summer, oil can degrade faster due to heat, leading to increased wear and tear. Check oil levels frequently and top up or change it as needed. Use the manufacturer's recommended oil type to ensure compatibility and efficiency.

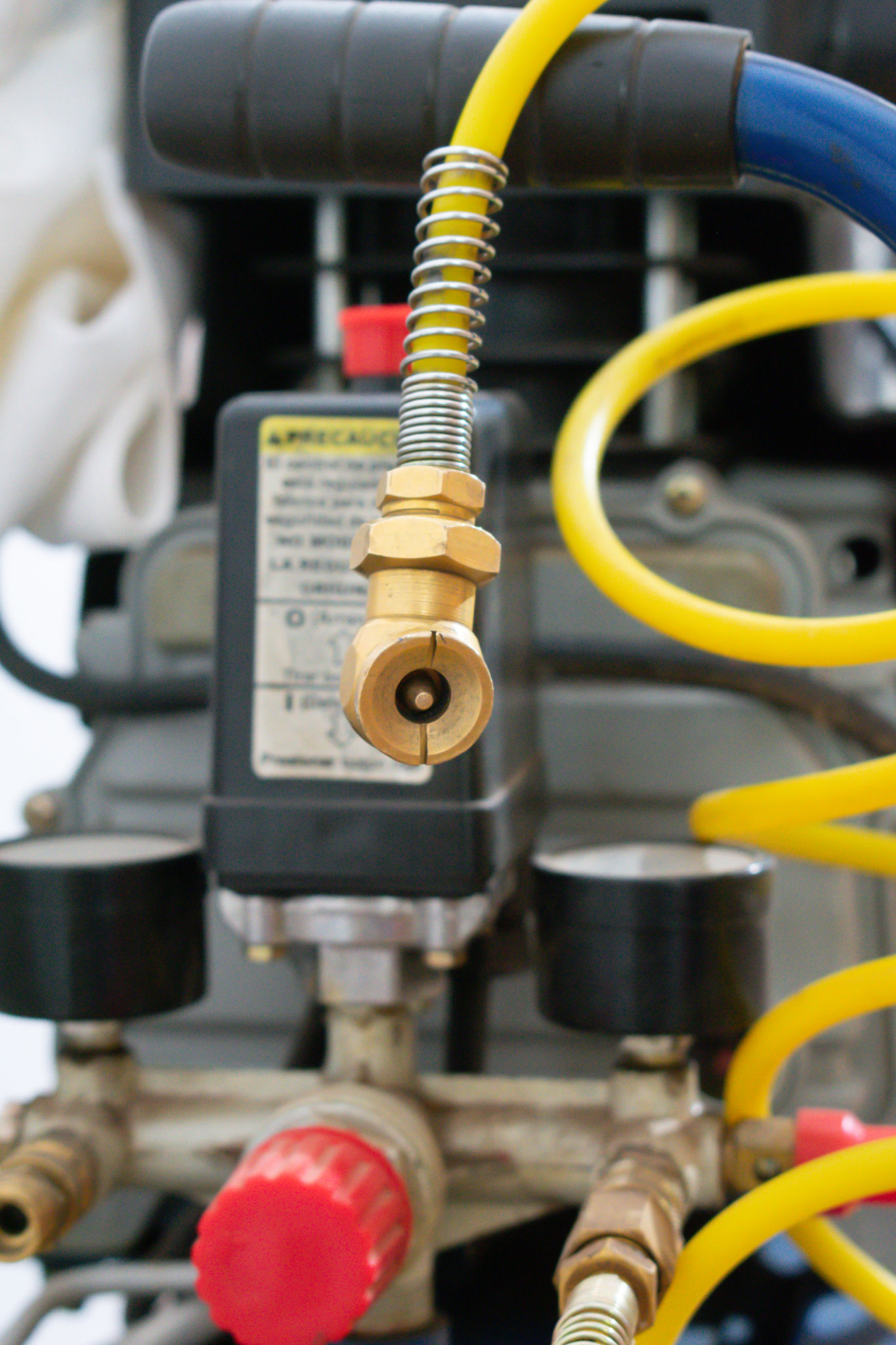

Inspect Hoses and Connections

Hoses and connections are often overlooked but can be sources of significant inefficiencies if not maintained properly. In summer, the heat can cause hoses to expand, leading to leaks or bursts. Regularly inspect hoses for any signs of wear, cracks, or leaks. Tighten connections to prevent air loss, which can reduce the efficiency of your compressor.

Maintain Adequate Ventilation

Air compressors generate a lot of heat, especially in warm weather. Proper ventilation is crucial to prevent overheating. Ensure that the compressor is placed in a well-ventilated area with enough space around it for air circulation. Consider using fans or air conditioning to help dissipate heat if necessary.

Schedule Regular Professional Inspections

While regular maintenance can be performed by operators, it's beneficial to schedule professional inspections at least once a year. Certified technicians can identify potential issues that may not be apparent during routine checks, ensuring that your air compressor remains in optimal condition throughout the summer.

Keep an Eye on Operating Temperatures

Monitoring the operating temperatures of your air compressor is essential during summer. High ambient temperatures can lead to overheating, which significantly impacts performance and could cause damage. Use temperature sensors or gauges to keep track of operating conditions and take corrective actions if temperatures rise above recommended levels.

Implement a Comprehensive Maintenance Schedule

Creating a comprehensive maintenance schedule will help ensure that all necessary tasks are completed consistently. Include daily, weekly, and monthly checks in your schedule, covering all aspects from filter changes to oil checks and hose inspections. This proactive approach will help you catch potential problems early, maintaining peak performance all summer long.

By following these summer maintenance tips for your air compressor, you can ensure that your equipment runs smoothly and efficiently throughout the season, minimizing downtime and maximizing productivity.