Top Myths About Air Compressor Maintenance: What You Really Need to Know

Understanding Air Compressor Maintenance Myths

When it comes to air compressors, maintenance is often surrounded by myths and misconceptions that can lead to costly mistakes. To keep your air compressor running efficiently, it's crucial to separate fact from fiction. Let's debunk some of the most common myths about air compressor maintenance.

Proper maintenance ensures that your air compressor runs smoothly and has a longer lifespan. However, many users believe that air compressors don't need regular servicing. This myth can lead to unexpected breakdowns and reduced efficiency.

Myth 1: Air Compressors Don't Need Regular Oil Changes

One common misconception is that air compressors don't require regular oil changes. While some compressors are designed to be oil-free, those that do use oil need regular changes to function optimally. Failing to do so can result in increased wear and tear, ultimately shortening the lifespan of your compressor.

Check the manufacturer's guidelines for your specific model, as the frequency of oil changes can vary. Regular oil changes not only help in maintaining efficiency but also prevent costly repairs in the long run.

Myth 2: You Can Ignore the Air Filter

Another prevalent myth is that the air filter doesn't need regular attention. In reality, a clogged air filter can significantly reduce the performance of your compressor. A blocked filter forces the motor to work harder, increasing energy consumption and wear.

To maintain optimal performance, it's essential to clean or replace the air filter according to the manufacturer's recommendations. This simple step can enhance efficiency and prolong the life of your compressor.

Myth 3: All Compressors Are Low Maintenance

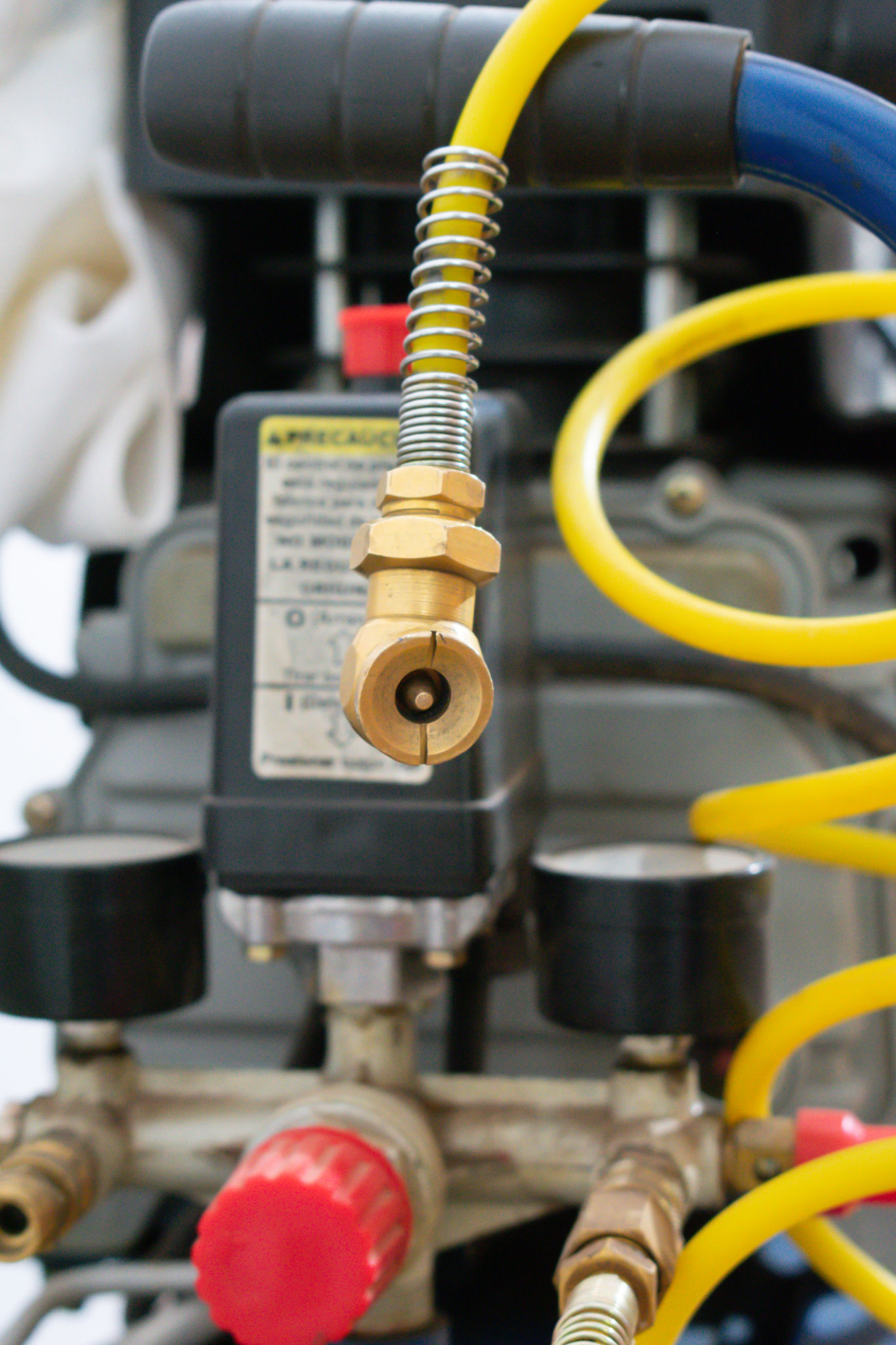

Many people assume that all air compressors require minimal maintenance. While some models are designed for easier upkeep, neglecting regular checks can lead to unexpected issues. It's crucial to regularly inspect belts, hoses, and other components for wear and tear.

A routine maintenance schedule can prevent small problems from becoming major repairs. Be proactive in checking for leaks, unusual noises, or vibrations, as these are often early indicators of issues that need addressing.

Myth 4: Overloading Is Not a Concern

There's a belief that air compressors can handle any workload without issues. However, overloading a compressor can lead to overheating and mechanical failure. Each model has a specific capacity, and exceeding this can cause significant damage.

Refer to your compressor's documentation to understand its limits and ensure you're operating within them. Avoiding overloads will not only extend its life but also improve energy efficiency.

Best Practices for Air Compressor Maintenance

Now that we've debunked some common myths, let's explore some best practices for maintaining your air compressor:

- Schedule Regular Inspections: Regularly check vital components like hoses, belts, and seals.

- Keep It Clean: Dust and debris can affect performance. Ensure your compressor and surrounding area are clean.

- Monitor Usage: Keep track of operating hours and schedule maintenance accordingly.

By understanding the importance of proper maintenance and recognizing these myths, you can ensure your air compressor remains reliable and efficient for years to come.